Growing pressure to transition to the circular economy and the desire to eliminate legacy additives is proving to be a conundrum for the plastics recycling sector. Richard McKinlay, Axion’s Head of Consulting, explores the issues and impacts on the industry.

Plastic products have been an integral part of our modern lives for some decades now, providing excellent functionality in myriad applications and sectors.

Recycling is an important part of the circular economy and to keep materials flowing, there will always be a need to recover and recycle plastics, wherever possible.

But when it comes to recycling these materials, plastics containing legacy additives – Persistent Organic Pollutants (POPS) – cannot be recycled due to restrictions aimed at eliminating risk to health and the environment.

There is an enormous amount of ‘legacy’ plastic in long life goods, such as electronics, construction and automotive products. For example, almost half of all plastics from waste electrical and electronic equipment (WEEE) cannot be recycled because their POPs content exceeds permitted levels. Inevitably, these ‘contaminated’ materials have to be incinerated.

These plastics can contain additives we now know are harmful to the environment or to human health, and therefore have since been restricted for use in new products under REACH regulations.

Consequently, the industry is facing a huge problem of how to recycle legacy products, some of which are in theory recyclable, but contain hazardous additives that are now restricted. This is making recycling more difficult, whereas in a circular economy, the process should be made easier. Achieving a circular economy for WEEE plastics is looking more distant because of more stringent POPs limits and the desire to be ‘toxic-free’.

Even the potential presence of legacy additives is enough to prevent recycling, and with costly laboratory analysis required to prove the absence of banned additives often recyclers will not process these ‘legacy’ plastics.

Now the burden of these legacy additives, and responsibility for them, is on waste managers and recyclers rather than the manufacturers who profited from them in the first place. Producers want to demonstrate ‘producer responsibility’ by ensuring their goods can be recycled, yet when it comes to items like waste electronics it is becoming more and more difficult.

Legally, POPS waste must be destroyed. As this waste is often mixed with non-POPs plastics, which cannot be separated, then the mixture needs to be destroyed and raw material resources are lost.

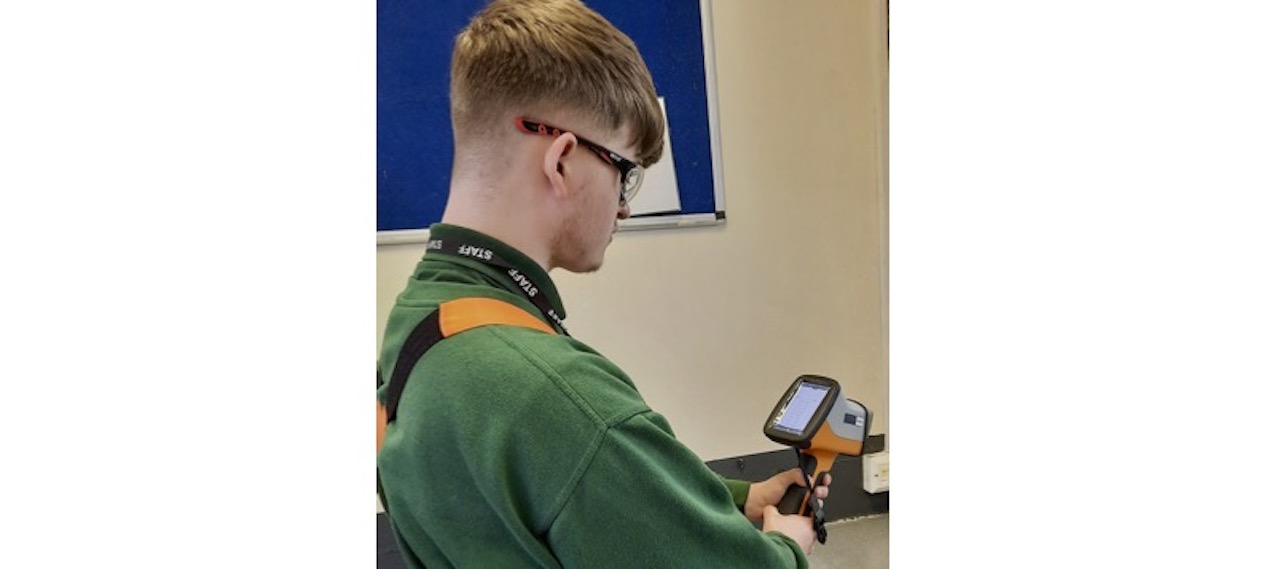

So, where does this leave us? Although technology is continually improving to be able to separate POPs, such as X-ray sorting to identify bromine, this comes at a high cost compared to conventional methods.

Then there is the constant threat of more additives becoming restricted and moving to the banned POPs list. Amidst all these regulations, there are still recycling targets to meet, and it seems the recyclers are left to deal with it all.

Stopping harmful additives at source in manufacturing is absolutely vital, but if they have historically been used, they will remain in the waste for many years. The ability of the waste industry to adapt must be considered when restricting more additives.

Ultimately, what is needed is a collaborative approach with manufacturers, recyclers and regulators all working together towards maximising what we can recycle and removing hazardous substances. Recyclers need continued cross supply chain support.

If regulations become too burdensome to recycle responsibly, the danger is that waste could be forced down illegal and unregulated routes leading to a worse environmental outcome in the future.